lower forming forces | high forming degrees

lower forming forces | high forming degrees

Hot forging for special screws & custom-made fasteners

Hot forging – precise, economical, and gentle on materials

In forging technology, the temperature of the workpiece determines the most suitable process. Hot forging is the preferred method for demanding materials such as nickel-based alloys, duplex steels, and high-temperature steels. These materials are cost-intensive, which is why chipless and material-friendly production is crucial.

Hot forging enables:

- High precision for complex geometries

- Cost-effective production without material loss

- Resilient components for extreme operating conditions

We manufacture fasteners and special screws in diameters from M6 to M160, from prototypes to large series – exactly according to your requirements.

What is hot forging and why is it the right choice?

During hot forming, the workpiece is heated to high temperatures in order to increase its formability and precisely produce complex shapes.

The decisive advantage over machining:

No chips are produced – and therefore no material loss. This is an enormous cost advantage, especially for expensive materials such as nickel-based alloys or duplex steels.

Technical advantages:

- Homogeneous microstructure for high fatigue strength

- Economical production even with complex geometries

- Ideal for high-strength and difficult-to-machine materials

Send inquiry now

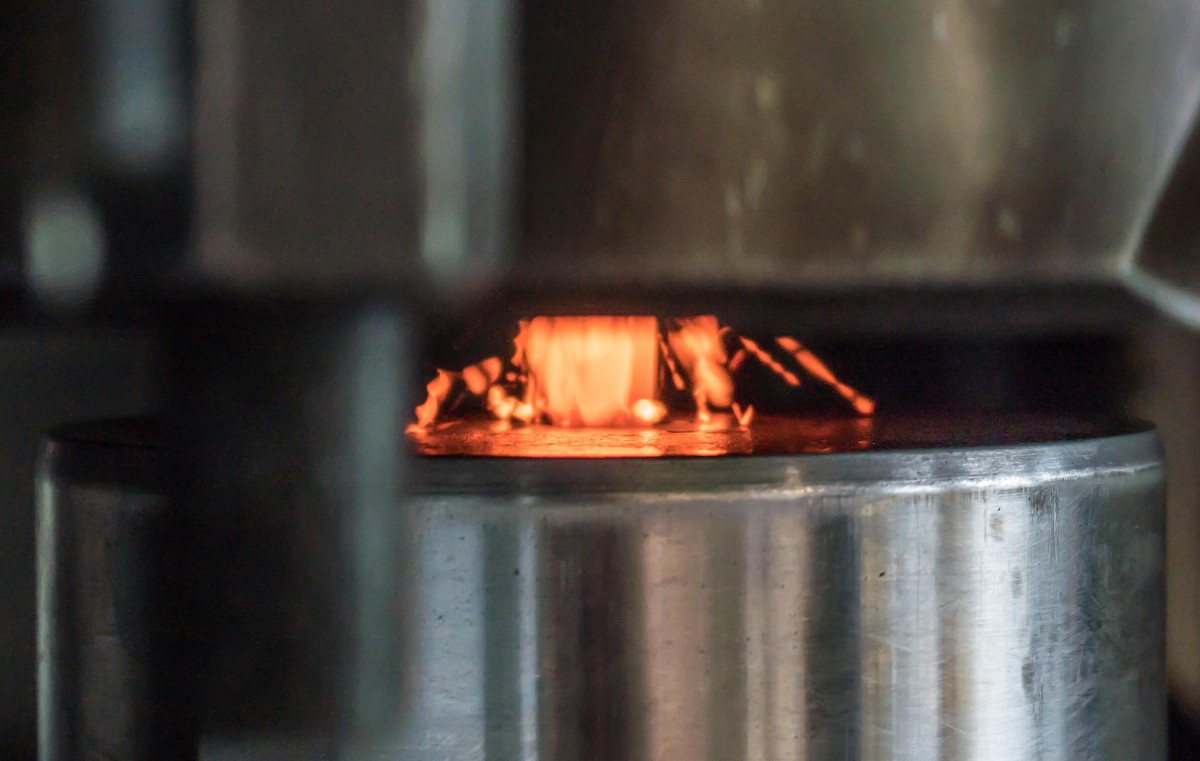

Hot forming of a custom-made special screw made of duplex steel – precise and gentle on materials for maximum load-bearing capacity.

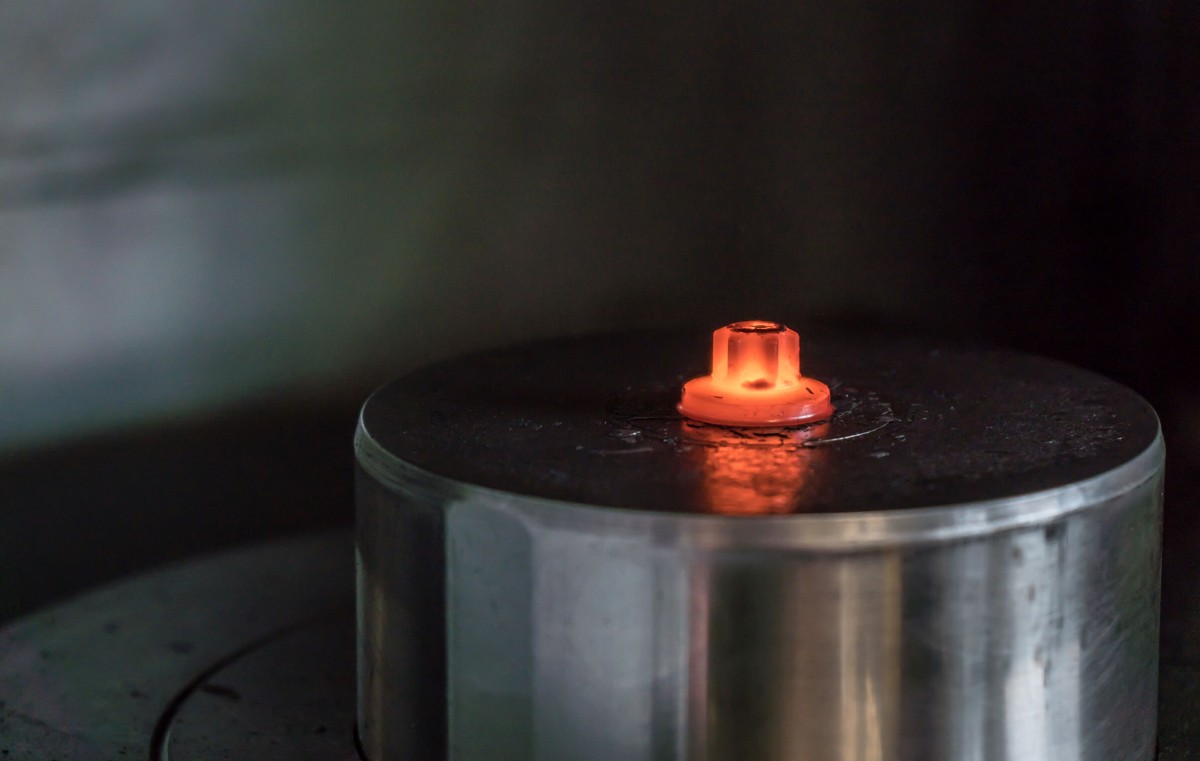

Formed special screw made of duplex steel – Güldner processes demanding materials such as duplex steels, nickel-based alloys, and high-temperature steels precisely and economically.

Advantages of hot forging for high-quality materials

Hot forging is the first choice for demanding C-parts made of:

- Nickel-based alloys

- Duplex steels

- High-temperature steels

The process ensures:

- Gentle treatment of materials without waste

- High strength and resilience

- Cost-effectiveness for complex geometries

View materials

Our manufacturing capabilities – from sample parts to large series

Whether prototypes, small series, or large series: Sonderschrauben Güldner offers maximum flexibility.

We manufacture hot-formed fasteners and special screws in diameters from M6 to M160 – exactly according to your requirements. This means you receive tailor-made solutions for any quantity.

Hot-formed special screw for construction machinery, engines, and hydraulic systems for construction machinery – Güldner manufactures precision fasteners for maximum loads and complex applications.

Submit your request for hot forging now

We offer a clearly structured request process for hot-formed parts – including technical advice, feasibility checks, and quick quotations.

Sonderschrauben Güldner GmbH & Co. KG collects and processes the personal data entered in the form in order to process the requested inquiry for you. Please note the marking of the mandatory fields on the forms. The legal basis for this processing of mandatory data is Art. 6 para. 1 lit. b GDPR, implementation of a pre-contractual measure. The processing of the data voluntarily provided by you is carried out on the basis of Art. 6 para. 1 lit. f GDPR. This permits processing that is necessary to safeguard our legitimate interests. Our legitimate interest is to have contact with you, our customers, to improve the quality of our advice and to be able to contact you more easily in the event of any queries. The data collected will only be stored by us for as long as is necessary to process your request and to contact you. It will then be deleted. Translated with DeepL.com (free version)

Additional data protection information, in particular on your rights to information, rectification, erasure, restriction of processing, objection and complaint, can be found in our privacy policy.