highest precision | for sophisticated drawing parts

highest precision | for sophisticated drawing parts

Precise CNC turned parts direct from the manufacturer - turned parts for the highest demands

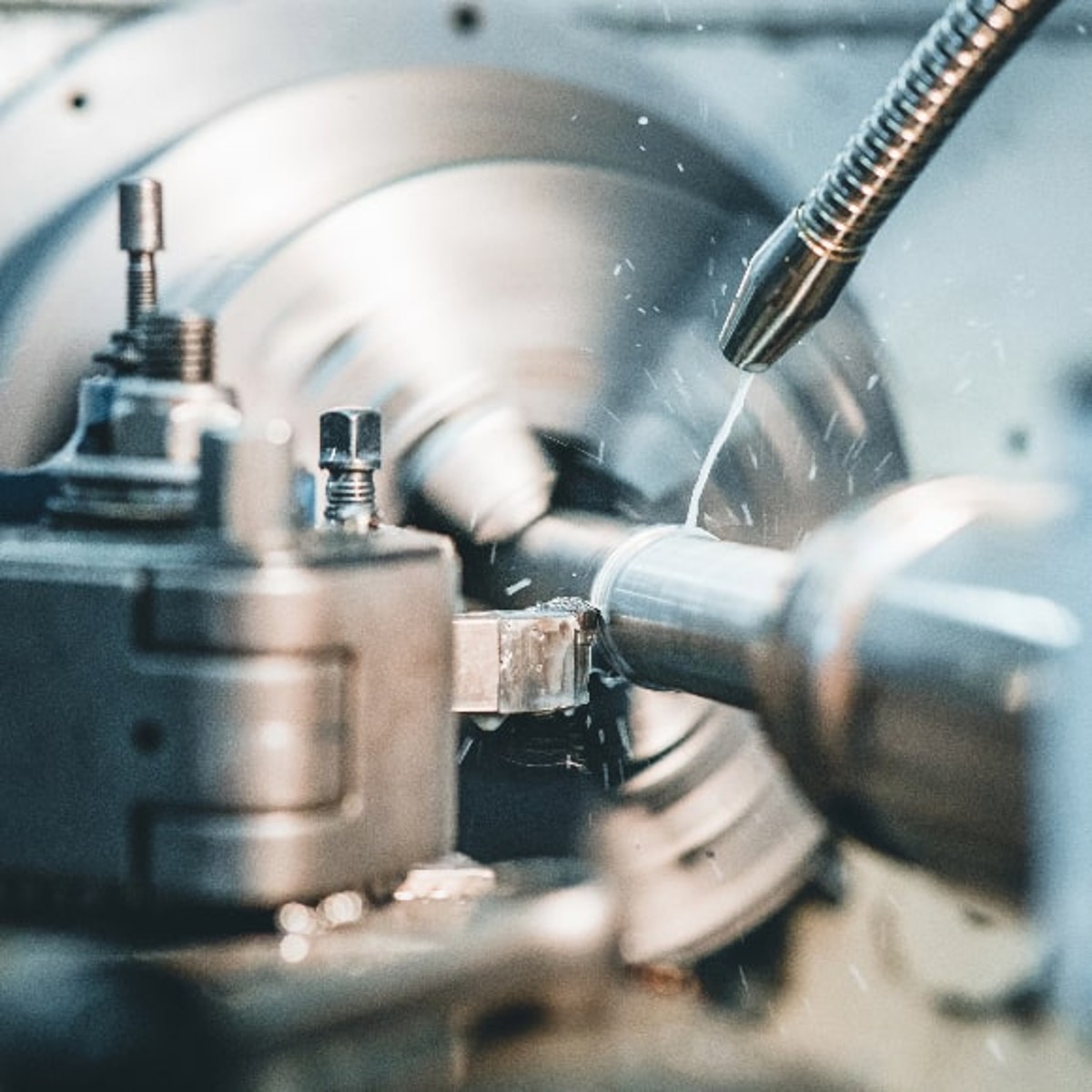

Turned parts are components that are produced by machining (turning). When turning CNC turned parts, a piece of raw material is mounted on a lathe and then turned while one or more cutting tools remove material to create the desired shape.

CNC turned parts can be made from all machinable materials as well as non-ferrous metals with different turning movements.

Turned parts, such as axles, bolts, screws, nuts, shafts and many other precision turned parts, are essential components in a variety of technical devices, including machinery, vehicles and electrical appliances. They are widely used in various industries, including automotive, aerospace, medical and electronics. Turned parts are important to enable mechanical functions and improve the performance and reliability of products.

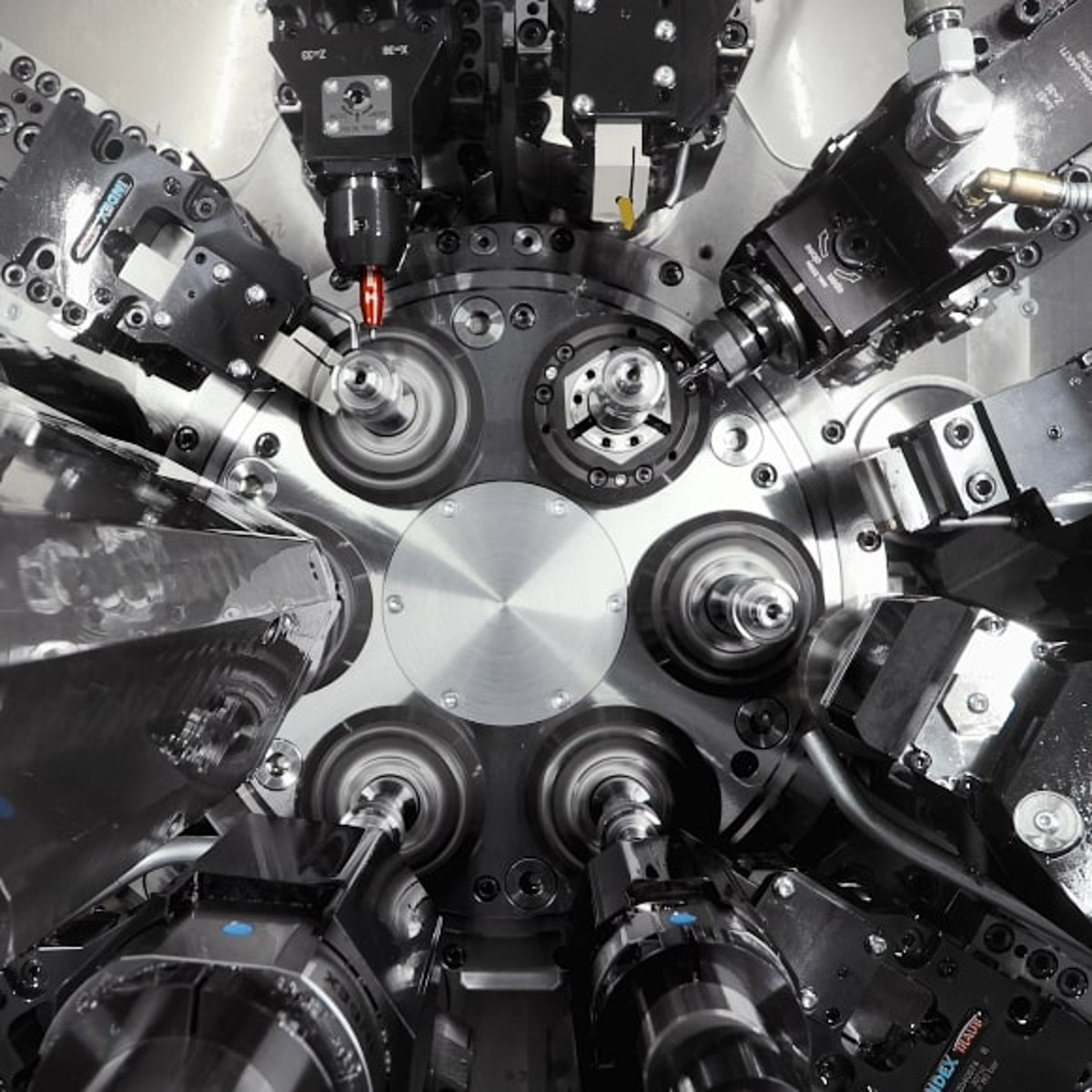

Efficient large-scale production of high-precision turned parts

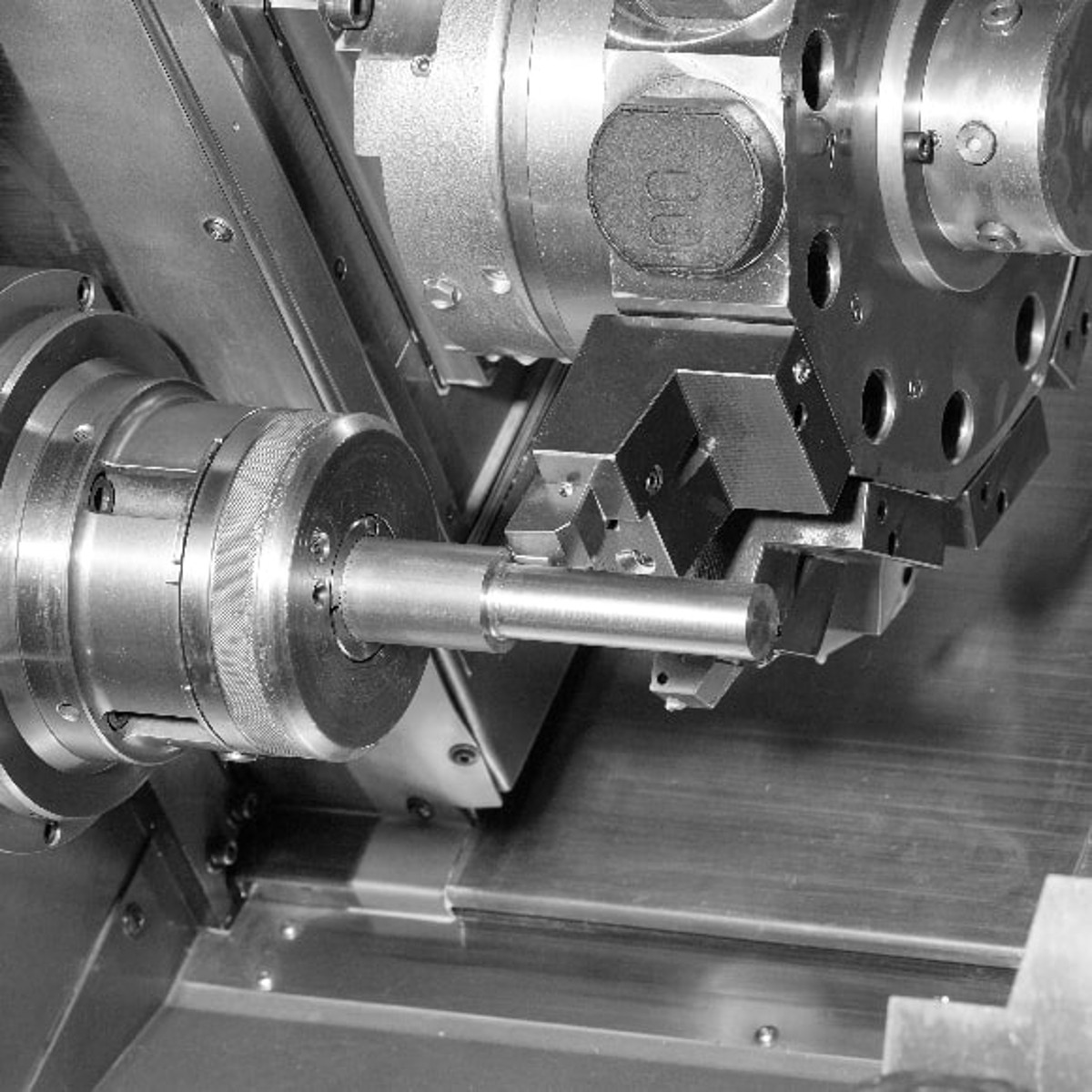

We manufacture complex turned parts in series production that require the highest precision. These precision turned parts can have different shapes and sizes and be made from special materials. They are often used in challenging applications. Specialist knowledge and modern machinery are required to achieve the desired shapes and tolerances. Series production requires efficient planning and control to ensure quality and productivity.

When you view and play embedded videos on www.gueldner.com, the provider (YouTube) may be able to store your access and analyze your behavior. If you activate the content, i.e. agree to view and play it, a cookie is placed on your computer to record that you have agreed to this in your browser. This cookie does not store any personal data.

For more information, please see our privacy policy and cookie page.

You can also use this link to access the video directly on the plattform of the provider: https://youtu.be/SY0MnQdo-Mg

We offer customized complete solutions for CNC turned parts that are tailored to the individual requirements of our customers. Flexibility and the ability to handle variable quantities are our focus.

Our CNC turning process enables us to produce high-precision turned parts, whether for small or large batch sizes. We use the latest CNC technology and have experienced specialists to achieve the desired shapes and specifications.

Our aim is to offer our customers a complete solution that covers the entire production process. This includes advice and collaboration on design optimization, material sourcing, CNC machining, quality control and on-time delivery.

Thanks to our flexible production capacities, we can react quickly to quantity changes and ensure cost-efficient production. Our aim is to meet our customers' requirements and provide them with high-quality CNC turned parts, whether they are small prototypes or large series productions.

Our customized complete solutions for CNC turned parts give our customers the assurance that their requirements are fulfilled and that they receive the desired parts in the required quantity.

Turned parts according to drawing

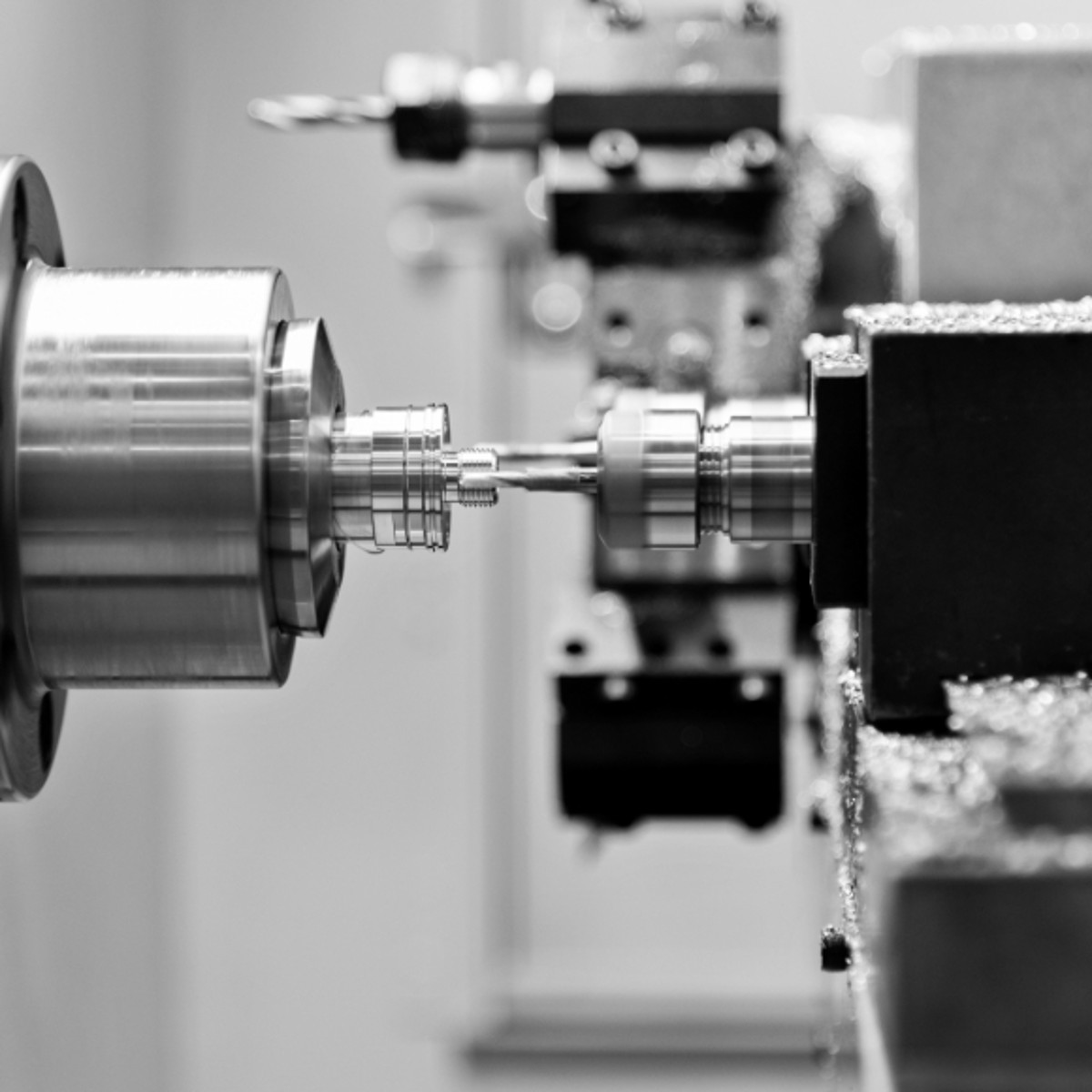

We produce CNC turned parts according to drawings, i.e. we manufacture them exactly to the specifications of your technical drawing or digital model. Precision turned parts often have to be manufactured according to special designs and strict tolerances. In addition, various machining processes can be used, such as turning, milling, drilling and other methods of machining your turned parts.

Once your turned part has been manufactured, it is checked to ensure that it corresponds exactly to the specifications of your drawing. This can be done using various measuring devices and methods.

In some cases, the turned part may require post-processing, such as heat treatment or surface finishing, to improve or protect its properties.

Request your non-binding offer now!

Would you like to get more information or request turned parts?

We are available to help you both online and by phone.

We will be happy to help you at any time! Feel free to send us an e-mail or give us a call!

+49 7932 9155 - 0

Email contact

Sonderschrauben Güldner GmbH & Co. KG collects and processes the personal data entered in the form in order to process the requested inquiry for you. Please note the marking of the mandatory fields on the forms. The legal basis for this processing of mandatory data is Art. 6 para. 1 lit. b GDPR, implementation of a pre-contractual measure. The processing of the data voluntarily provided by you is carried out on the basis of Art. 6 para. 1 lit. f GDPR. This permits processing that is necessary to safeguard our legitimate interests. Our legitimate interest is to have contact with you, our customers, to improve the quality of our advice and to be able to contact you more easily in the event of any queries. The data collected will only be stored by us for as long as is necessary to process your request and to contact you. It will then be deleted. Translated with DeepL.com (free version)

Additional data protection information, in particular on your rights to information, rectification, erasure, restriction of processing, objection and complaint, can be found in our privacy policy.